Dynamic Pass Boxes

In Stock

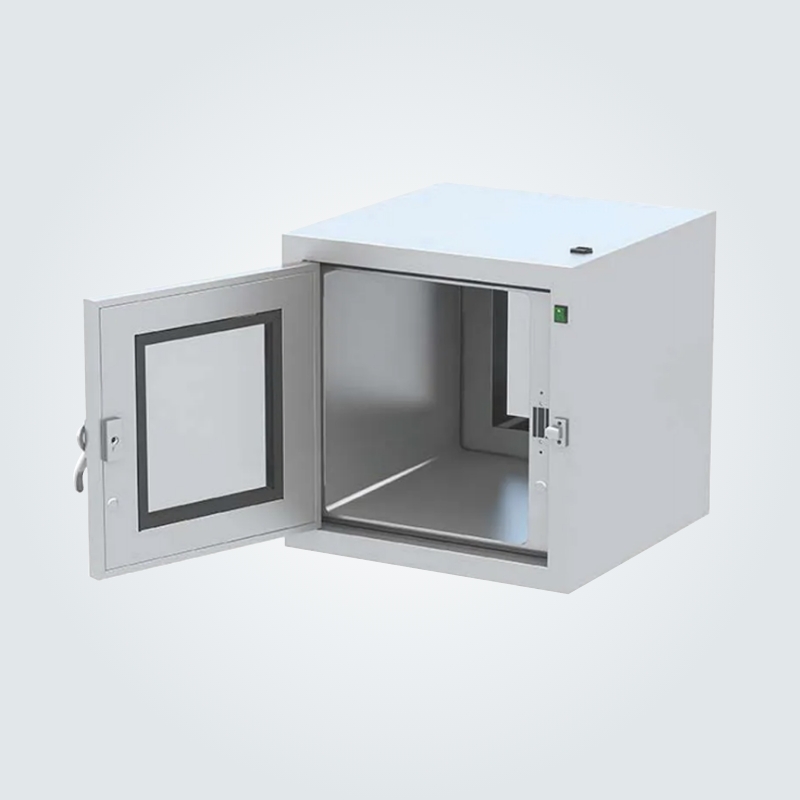

Dynamic Pass Boxes

In Stock

We specialize in manufacturing and installing high-performance Dynamic Pass Boxes (DPBs)—an essential element in controlled environments for transferring materials between clean and less clean areas without compromising the integrity of the cleanroom. Unlike static models, dynamic pass boxes feature active air circulation with HEPA filtration, making them ideal for environments requiring strict contamination control.

Dynamic Pass Boxes are extensively used in pharmaceutical production units, biotech laboratories, cleanroom manufacturing, hospitals, and electronics industries, where sterility and cleanliness are non-negotiable. These pass boxes are equipped with advanced air filtration systems that purge and filter airborne contaminants before and after the transfer process, ensuring that only sterile materials enter critical zones.

Features

HEPA Filtered Air Circulation: Integrated HEPA filters (99.97% efficiency @ 0.3μm) ensure particle-free air inside the pass box.

Electromagnetic Interlocking Doors: Prevents simultaneous opening of both doors, thereby minimizing cross-contamination risk.

SS 304/316 Construction: Robust stainless steel body ensures hygiene, corrosion resistance, and long-term durability.

UV Sterilization (Optional): Built-in UV lamp for added microbial control.

Pressure Differential Monitoring: Ensures consistent airflow and filter efficiency.

Low Noise, High Efficiency Blower: Maintains clean air circulation with minimal disturbance.

Indicator Lamps & Alarm Systems: Visual and audible alerts for operational safety and door status.

Technical Specification

Material: SS 304 / SS 316 (Matt/Glossy Finish)

Filter Type: Pre-filter (5μ) + HEPA filter (0.3μ)

Air Velocity: 90 ± 20 FPM

Filtration Efficiency: 99.97% at 0.3 microns

Blower Unit: Centrifugal type, low-noise, energy-efficient

UV Lamp (Optional): 8W / 15W germicidal tube

Door Interlock: Electromagnetic with LED indicators

Power Supply: 230V AC, 50Hz

Size Options: Customizable to client specifications

Customer Benefits

Improved Cleanroom Integrity: Active air circulation with HEPA filtration ensures high-level contamination control.

Enhanced Safety: Prevents particulate transfer from uncontrolled to sterile areas.

Regulatory Compliance: Built to comply with GMP, WHO, ISO 14644, and FDA guidelines.

Flexible Customization: Sizes, materials, and control options can be tailored to specific facility needs.

Operational Efficiency: Reduces cleanroom downtime and streamlines material transfer processes.

User-Friendly Interface: Clear indicators and smooth operation minimize training and errors.

Low Maintenance: Built for continuous use with minimal service requirements.

Like what you see? Request a quote from us.

Similar Products

Find other vacancies that suits your profile.